Aluminium Box I have completed my prototype solar light. It is working as it should. The process of this prototype solar light began On Tuesday May the 13th.

We had a brief given to us by a man named Terry Hawkinsthe brief was to modify a circuit and make an aluminium box that would fit the circuit.

We were given working solar panel lights which were purchased from the warehouse for a cheap amount of money. We disassembled the solar panel light as it was in a cheap plastic container. Were then removed the circuit and all components from the cheap plastic container. We did this so we could modify the circuit and add brighter LED’s.

After we disassembled the circuit we put all the pieces into a bag. We then began to make the aluminium box. Terry had all the templates of the box already cut to save time. The aluminium template was cut in the cam machine because it is a lot faster than manually cutting it.

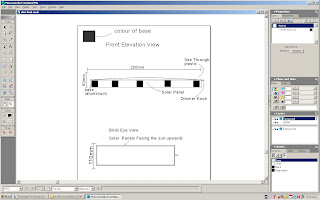

We first marked lines on the aluminium template that showed were the bending points were. We then folded the sides that stuck out of the aluminium template at 90 degree angles. After all 4 sides were bent the aluminium template formed a box shape.

Then after the box was folded we made brackets for it. These were made by cutting out bits out of the scrap aluminium with the guillotine .We marked the bending points in the bits of scrap aluminium then bent them into shape – Bending bit of scrap aluminium at a 90 degree angle so they were ‘L’ shaped. We then marked out the points were the rivets could go through we drilled them out using a 2.5 drill bit. We had to put the holes in specific places to prevent the rivets from hitting each other when inserted in the box. Then we attached the brackets onto the box. The bottom of the box was now completed.

The next step was to create the top plate of the box this again was cut out with the cam machine to save time. We marked out the folding points then bent the edges at a 90 degree angle. Then drilled holes and attached it to the bottom of the box using screws. Modifying The Circuit The circuit had to be modified. We modified it by Adding two stronger and brighter LED’s (there used to be one weak LED before undergoing modification) We also changed the circuit from series to parallel. In the process of changing the circuit from series to parallel I had a problem. The problem was that the circuit didn’t work. I did a complete analysis of the circuit and to my dismay I discovered that my wire connection to the circuit board had broken so I had to re-solder the joint. This corrected the functionality of my circuit We also added a new battery connector. Once my circuit was working I attached it into my Aluminium box. Then I discovered another problem. The wire connection was touching the aluminium box and causing the circuit to short circuit. So I took out the circuit of the box and disconnected the wire connection and placed heat shrinkable tube and made sure all other connections had heat shrinked tube on them to prevent short circuiting. This solved my problem.

I then attached the solar panel to the circuit. I made the LED’s stick out of the box and the stayed there with hot glue. The solar panel was stuck onto the box with silicon. The light now works as it should.

This process was completed within the given time frame

Chirag =)