Monday, November 10, 2008

Week 5 Final

During this weekend i came in on saturday.on saturday i got alot of work completed.I connected my solar panels to the box with silicon.I also cut out a bit of white plastic so i could hide the circuitry.On sunday i also came in on sunday i drilled holes for my LEDs in my white plastic.And i got all of my circuits working.my lioght was complete.then as i was packing up two of the LEDs stopped working i thougt it had short circuited.on monday i came in for period one and i fixed the LED problem.the battery had fallen out so i glued all the batteries in their packs.i then closed it up and the light was finished.Today i am uploadind images of my progress and uploadind my evaluations.

Churr

Churr

How My Completed Light Meets The Brief

How My Completed Light Meets The Brief

I have met the criteria in the brief. The brief stated that the light must be

-Able to withstand the Coramandell weather.

-Within a $60 budget

-Self powered

-Turn off in daylight and off in the night

My finished product is rustproof because the bulk of it is made of aluminum and the top plastic part is acrylic which also is non corrosive.

It is weather proof because I have sealed off the entire light with silicon sealant. The silicon sealant will not allow any water through. Therefore because its rust proof and weather proof my light can withstand the Coramandell weather.

My Finished product uses a solar panel in the circuit. The solar panel is a self powering component

The circuits I used all have LDRs in them. this makes the lights to turn off in sunlight , when the solar panel charges and turns on at night when the light was needed.

All the materials used in the making of my solar panel light were all relatively cheap. Therefore my completed light is under the $60 budget.

Evaluation Of My Completed Design

Evaluation Of My Completed Design

My completed solar light differs a lot to my original design created on macromedia freehand .to get ideas for my design we went on a field trip around Wellington city to see the lights that were planted around the city. To my amazement there were a lot of different designs. We drew sketches of the designs that we liked. Out of all of the designs I drew, there was one particular idea that appealed to me. This was a light that was wall mounted. I didn’t like the actual design of the light but the fact that it was wall mounted inspired me to create a wall mountable solar light.

On freehand I came up with the original design. It was simple. Then I made the design on solid works. Making the light on solidworks was a great experience because I got to see the flaws on my design. A major flaw solidworks alerted me of was that having the solar panel where it was a bit impractical .i discussed this problem with my teacher terry advised me to add more solar panels on to the top of my light .This way my light would be gaining optimum sunlight and also gaining more power because I would have 4 solar panels instead of just one. So I created my new modified design on solidworks

I then began to make my mockup of my final design. The mockup was easily made because of the simplicity of my design. I was happy with my mock up because it was a good size. Everything was going to plan.

Then on the computer I made the net of my aluminium base. Then I encountered another problem. The net was much too large to fit into the Roland cam machine. So I decided to make my final design a bit smaller and it would only fit three solar panels on it.

So the net was cut out in the cam machine. I got the cam machine t not only cut out the net but I also got it to cut grooves on the lines where the net would be folded. I did this so the folds would be perfect and easy to do. After the net was folded I decided that it would not need brackets because the net held its shape without any aid and brackets would make it look less simple.

I made the top plastic part. I would make this by using the vacuum former. I made the mould of wood. In my original free hand design the plastic top part was curved. this was a problem as the mould was going to be too hard and time consuming to make with a curve so I changed the shape of it.

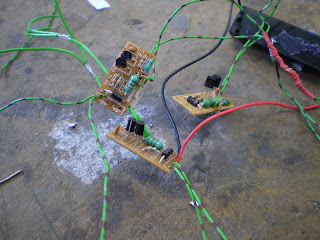

I then made three circuits. I had a problem with the circuits. the tracking had fallen off the circuits in some parts. I fixed this by adding solder were the tracking originally was .All three of the circuits worked. I added two higher powered Leeds in parallel to each circuit. The circuits produce good light.

Then I siliconed the box where the brackets would have been so the box wont let any water into it. Then I added the solar panels to the top of the box. Then I connected the solar panels to the circuits. I had a really good idea instead of just sealing the box shut with silicon which would have looked messy I cut out a bit of whie plastic and drilled six holes in it for the LEDs.I used white plastic so that the circuitry would not be visible.It looks real good.

I am very happy with the way my final design came out. It has been a long process but I have learned much from it. I think my design is very cool not only because it looks cool but the fact it can easily be wall mounted or kept on the ground is a bonus. I don’t think if I made it again I would not make any changes.

By Chirag Patel 11DTM, 11HST

My completed solar light differs a lot to my original design created on macromedia freehand .to get ideas for my design we went on a field trip around Wellington city to see the lights that were planted around the city. To my amazement there were a lot of different designs. We drew sketches of the designs that we liked. Out of all of the designs I drew, there was one particular idea that appealed to me. This was a light that was wall mounted. I didn’t like the actual design of the light but the fact that it was wall mounted inspired me to create a wall mountable solar light.

On freehand I came up with the original design. It was simple. Then I made the design on solid works. Making the light on solidworks was a great experience because I got to see the flaws on my design. A major flaw solidworks alerted me of was that having the solar panel where it was a bit impractical .i discussed this problem with my teacher terry advised me to add more solar panels on to the top of my light .This way my light would be gaining optimum sunlight and also gaining more power because I would have 4 solar panels instead of just one. So I created my new modified design on solidworks

I then began to make my mockup of my final design. The mockup was easily made because of the simplicity of my design. I was happy with my mock up because it was a good size. Everything was going to plan.

Then on the computer I made the net of my aluminium base. Then I encountered another problem. The net was much too large to fit into the Roland cam machine. So I decided to make my final design a bit smaller and it would only fit three solar panels on it.

So the net was cut out in the cam machine. I got the cam machine t not only cut out the net but I also got it to cut grooves on the lines where the net would be folded. I did this so the folds would be perfect and easy to do. After the net was folded I decided that it would not need brackets because the net held its shape without any aid and brackets would make it look less simple.

I made the top plastic part. I would make this by using the vacuum former. I made the mould of wood. In my original free hand design the plastic top part was curved. this was a problem as the mould was going to be too hard and time consuming to make with a curve so I changed the shape of it.

I then made three circuits. I had a problem with the circuits. the tracking had fallen off the circuits in some parts. I fixed this by adding solder were the tracking originally was .All three of the circuits worked. I added two higher powered Leeds in parallel to each circuit. The circuits produce good light.

Then I siliconed the box where the brackets would have been so the box wont let any water into it. Then I added the solar panels to the top of the box. Then I connected the solar panels to the circuits. I had a really good idea instead of just sealing the box shut with silicon which would have looked messy I cut out a bit of whie plastic and drilled six holes in it for the LEDs.I used white plastic so that the circuitry would not be visible.It looks real good.

I am very happy with the way my final design came out. It has been a long process but I have learned much from it. I think my design is very cool not only because it looks cool but the fact it can easily be wall mounted or kept on the ground is a bonus. I don’t think if I made it again I would not make any changes.

By Chirag Patel 11DTM, 11HST

Tuesday, November 4, 2008

Week 4 Term 4 08

On friday i finished all three circuits. they are all working very well.I have drilled holes for the three solar panels.today after school i am going to do some practical work because i want to get my light completed ASAP.hopefully i will get all the solar panels attatched to the box. I will also want to finish the aluminium piece which covers the circuit.

CHEA!!!!!!!!!!!!!!!

CHEA!!!!!!!!!!!!!!!

Tuesday, October 28, 2008

Week 3 Term 4 08

I came on satrday this week and i completed 2 circuits.I had a bit of trouble with one one of my circuits because the leds wires were touching each other causing the circuit to short circuit.I fixed this problem by putting insulation tape on the wires.On tuesday i completed my third circuit i now need to only complete 1 more circuit.Today i am blogging and updating calender and i will do my video interview.On friday i will do my last circuit and cut out another pice of aluminium to cover the circuits so it dont look to messy.

Tuesday, October 21, 2008

Week 2 Term 4 08

On friday i begun working on my circuits I am basically done with modifying that circuit.On Tuesday i completed the circuit.Today i am blogging and will update my calender.

Monday, October 13, 2008

Tuesday Week 1 Term 4 08

Today i am Blogging abot what i am to do this week and updating my calender.Tommorow on wensday i am going to hopefully be doing practical and i will be starting to create circuits for my light. On friday i will be continuing with the process of creating circuits.

Tuesday, September 23, 2008

Week 10 Term 3 08

On friday i cut out my plastic mould .Yesterday we did origami because we had a releiver.Today we are blogging and updating calender.Tommorow i will complete the plastic mould and silicon my box.

Tuesday, September 16, 2008

Week 9 Term 3 08

On Friday two Weeks ago i completed my Styrofoam mould and when i when to get the plastic sheet to melt i saw Jonos Styrofoam mould had melted when the melted sheet can in contact with it, so i was buggered and i had made the mould for nothing.On Tuesday i did practical work and with the help of my good friend Ryan completed a wooden mould.so i cut out a plastic sheet and the encountered another problem.The seals in the vacuum form machine were stuffed.So terry fixed this and then at lunch i came back and i used the machine and completed a perfect mould.Today i am updating my blogger.On friday we only have one period of DTM so i will cut out my plastic mould and figure out how to attach it to my box

Tuesday, September 2, 2008

Week 7 term 3 08

On tuesay we did practical.I was going to carve out the shape of my plastic top in the Styrofoam using a sharp tool.but this would make the plastic piece have a very rough finish.so i discussed what to do with mr hawkins and he came to the conclusion that i would cut out the grove with the ban saw the allow the plastic to form on top of that.today i am blogging and am going to draw the groove on the computer so the cut will be perfect

Tuesday, August 26, 2008

Week 6 Term 3 08

On Friday i Begun to make brackets for my box.i made eight brackets.(i only need four but i thought i should make back up ones.)after folding all the brackets and drilling holes into each on i tried to attach them to the box.They did not fit as I am putting the brackets on the inside so my box looks mint.so now i have to attach my spares.

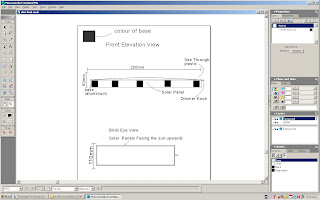

On tuesday I did a checklist of my blog .everything is done and updated except one or two things.I did my 2D engineering drawing for my design.

Today i am blogging and uploading images of my brackets in progress.

churrr

On tuesday I did a checklist of my blog .everything is done and updated except one or two things.I did my 2D engineering drawing for my design.

Today i am blogging and uploading images of my brackets in progress.

churrr

Monday, August 25, 2008

Tuesday, August 19, 2008

term 3 week 5 o8

On Friday i made a new net of my light.This net was a modified one of my original because my original was to big for the cam machine.the new net is a smaller size although this is good because even though its smaller it can fit four 40x40 solar panels on it.this will produce a lot of light.Then i cut my net out in the cam machine.Yesterday i cleaned up my net and took a lot of pictures of my progress of the folding process.Today i am blogging and uploading images that were taken yesterday.

...................................................................................................Today i have been thinking about my final design. Since my folds i have made are really good i am going to put the brackets on the inside of the box so it looks pro.Also after the circuit is complete i may attach it to the bottom of the box then i may put a reflective plastic on top of that (so more light will Show)then the LEDs will be on top of that.then a see through plastic will be put on top of that (this will be a bit bent so the light will spread well.)

chuuch

...................................................................................................Today i have been thinking about my final design. Since my folds i have made are really good i am going to put the brackets on the inside of the box so it looks pro.Also after the circuit is complete i may attach it to the bottom of the box then i may put a reflective plastic on top of that (so more light will Show)then the LEDs will be on top of that.then a see through plastic will be put on top of that (this will be a bit bent so the light will spread well.)

chuuch

Tuesday, August 12, 2008

Monday, August 11, 2008

Tuesday Week 4 Term 4 08

today im editing all my posts and giving them all the correct labels so i will not have to do it tommorow.tommorow i am going to work on my solid works design because my net will not fit in the cam machine.i am going to remove 1 solar panel so it can fit into the cam machine.my light when it is complete will be a bit smaller then planned but this is good because the light will be more discrete.on friday i will make a new net that will fit in the cam machine then get it cut out the dimensins of the net will be 300x210 mm

Thursday, August 7, 2008

Tuesday, August 5, 2008

Week 3 Term 3 08

On last friday I was on the computers in the DTM room,I had heaps done .i did a bit of bloging and i did a new solid works image of my new aand improved design.i also made a blog that justified my new design.on solid works i made another assembled light,

churrr

churrr

Monday, August 4, 2008

Thursday, July 31, 2008

Modification Justification And Rendered Solid Works Image Of Final Design To My Light Design

I have decided to modify my original design of my 'Slim" light design.there are going to be two main changes.

1.I have decided to not use the large solar panel because of the size of it.but instead to use 5 of the 40mm by 40mm solar panels..

2.Also the height of the base will have to become taller so the solar panels will fit on the base. I am increasing the base by 20mm so now the height of the base will be 60mm.

The solar panels will be placed on the side of the base of the light and when the light is wall mounted the solar panels will face up to the sky - this will allow maximum sunlight to the solar panels therefore I will be able to use more lights in the circuit.

Chirag

Tuesday, July 29, 2008

Week 2 Term 3 08

On friday i edited my template light evaluation and did practical for the rest of the periods.In practical i begun to make my mockup of my final light design.On tueday i completed my mockup of my final light design.I have discussed with terry about a major modification to my light .I am going to add 5 of 4 small solar panels to my final light design the will be added to the side of it to produce more light.

Tuesday, July 22, 2008

Week 1 Term 3 08

Yesterday we went on the computers and got given a partener and we had to place feedback on each others final design.in my feedback that was given to me by the great James Croft.today we are udatting our blog i also reposted my template light evaluationb and added some modifications to it on fri we have double prac

Template Light Evaluation 3.2

I have just completed my prototype solar light. It is working as it should. The process of this prototype solar light began On Tuesday May the 13th.

We had a brief given to us by a man named Terry Hawkins

The brief was to modify the circuit and make an aluminium box that would fit the circuit.

We were given working solar panel lights which were purchased from the warehouse for a cheap amount of money. We disassembled the solar panel light as it was in a cheap plastic container. We then removed the circuit and all components from the cheap plastic container. We did this so we could modify the circuit and add two LED’s.

After we disassembled the circuit we put all the pieces into a bag. We then began to make the aluminium box. Terry had all the templates of the box already cut to save time. The aluminium template was cut in the cam machine because it is a lot faster than manually cutting it.

Aluminium Box

We first marked lines on the aluminium template that showed were the folding points were. We then folded the aluminium template into a box shape. Each bend was made with a 90 degree angle. Then after the box was folded we made brackets for it.

The brackets were made by cutting out bits out of scrap aluminium with the guillotine. We marked the bending points in each bit of scrap aluminium then bent them into shape at a 90 degree angle.

We then marked out the points were the rivets could go through we drilled them out using a 2.5 drill bit. We had to drill the holes in specific places to prevent the rivets hitting each other in the box. Then we attached the brackets onto the box with aluminium rivets. The bottom of the box was now completed.

Then we made the top plate of the box this again was cut out with the cam machine to save time. We marked out the folding points then bent the edges at a 90 degree angle. This was followed by drilling holes and attaching the top plate to the bottom of the box. Then I screwed it on the box. The box was now completed.

Modifying The Circuit

The circuit had to be modified. We modified it by Adding two stronger and brighter LED’s (there used to be one weak LED before undergoing modification) we also changed the circuit from series to parallel. I had a bit of trouble with changing the circuit from series to parallel. I completed a full analysis of my circuit and to my dismay there was a dry joint so I fixed this problem.

We also added a new battery connector. Once my circuit was working I attached it into my Aluminium box and made sure all connections had heat shrinked tube on them to prevent short circuiting. I then attached the solar panel to the circuit. I made the LED stick out of the box and the stayed there with hot glue. The solar panel was stuck onto the box with silicon.

The light now works as it should.

This process was completed in the given time frame

Chirag =)

We had a brief given to us by a man named Terry Hawkins

The brief was to modify the circuit and make an aluminium box that would fit the circuit.

We were given working solar panel lights which were purchased from the warehouse for a cheap amount of money. We disassembled the solar panel light as it was in a cheap plastic container. We then removed the circuit and all components from the cheap plastic container. We did this so we could modify the circuit and add two LED’s.

After we disassembled the circuit we put all the pieces into a bag. We then began to make the aluminium box. Terry had all the templates of the box already cut to save time. The aluminium template was cut in the cam machine because it is a lot faster than manually cutting it.

Aluminium Box

We first marked lines on the aluminium template that showed were the folding points were. We then folded the aluminium template into a box shape. Each bend was made with a 90 degree angle. Then after the box was folded we made brackets for it.

The brackets were made by cutting out bits out of scrap aluminium with the guillotine. We marked the bending points in each bit of scrap aluminium then bent them into shape at a 90 degree angle.

We then marked out the points were the rivets could go through we drilled them out using a 2.5 drill bit. We had to drill the holes in specific places to prevent the rivets hitting each other in the box. Then we attached the brackets onto the box with aluminium rivets. The bottom of the box was now completed.

Then we made the top plate of the box this again was cut out with the cam machine to save time. We marked out the folding points then bent the edges at a 90 degree angle. This was followed by drilling holes and attaching the top plate to the bottom of the box. Then I screwed it on the box. The box was now completed.

Modifying The Circuit

The circuit had to be modified. We modified it by Adding two stronger and brighter LED’s (there used to be one weak LED before undergoing modification) we also changed the circuit from series to parallel. I had a bit of trouble with changing the circuit from series to parallel. I completed a full analysis of my circuit and to my dismay there was a dry joint so I fixed this problem.

We also added a new battery connector. Once my circuit was working I attached it into my Aluminium box and made sure all connections had heat shrinked tube on them to prevent short circuiting. I then attached the solar panel to the circuit. I made the LED stick out of the box and the stayed there with hot glue. The solar panel was stuck onto the box with silicon.

The light now works as it should.

This process was completed in the given time frame

Chirag =)

Thursday, July 3, 2008

Template Light Evaluation 3.2

Aluminium Box I have completed my prototype solar light. It is working as it should. The process of this prototype solar light began On Tuesday May the 13th.

We had a brief given to us by a man named Terry Hawkinsthe brief was to modify a circuit and make an aluminium box that would fit the circuit.

We were given working solar panel lights which were purchased from the warehouse for a cheap amount of money. We disassembled the solar panel light as it was in a cheap plastic container. Were then removed the circuit and all components from the cheap plastic container. We did this so we could modify the circuit and add brighter LED’s.

After we disassembled the circuit we put all the pieces into a bag. We then began to make the aluminium box. Terry had all the templates of the box already cut to save time. The aluminium template was cut in the cam machine because it is a lot faster than manually cutting it.

We first marked lines on the aluminium template that showed were the bending points were. We then folded the sides that stuck out of the aluminium template at 90 degree angles. After all 4 sides were bent the aluminium template formed a box shape.

Then after the box was folded we made brackets for it. These were made by cutting out bits out of the scrap aluminium with the guillotine .We marked the bending points in the bits of scrap aluminium then bent them into shape – Bending bit of scrap aluminium at a 90 degree angle so they were ‘L’ shaped. We then marked out the points were the rivets could go through we drilled them out using a 2.5 drill bit. We had to put the holes in specific places to prevent the rivets from hitting each other when inserted in the box. Then we attached the brackets onto the box. The bottom of the box was now completed.

The next step was to create the top plate of the box this again was cut out with the cam machine to save time. We marked out the folding points then bent the edges at a 90 degree angle. Then drilled holes and attached it to the bottom of the box using screws. Modifying The Circuit The circuit had to be modified. We modified it by Adding two stronger and brighter LED’s (there used to be one weak LED before undergoing modification) We also changed the circuit from series to parallel. In the process of changing the circuit from series to parallel I had a problem. The problem was that the circuit didn’t work. I did a complete analysis of the circuit and to my dismay I discovered that my wire connection to the circuit board had broken so I had to re-solder the joint. This corrected the functionality of my circuit We also added a new battery connector. Once my circuit was working I attached it into my Aluminium box. Then I discovered another problem. The wire connection was touching the aluminium box and causing the circuit to short circuit. So I took out the circuit of the box and disconnected the wire connection and placed heat shrinkable tube and made sure all other connections had heat shrinked tube on them to prevent short circuiting. This solved my problem.

I then attached the solar panel to the circuit. I made the LED’s stick out of the box and the stayed there with hot glue. The solar panel was stuck onto the box with silicon. The light now works as it should.

This process was completed within the given time frame

Chirag =)

We had a brief given to us by a man named Terry Hawkinsthe brief was to modify a circuit and make an aluminium box that would fit the circuit.

We were given working solar panel lights which were purchased from the warehouse for a cheap amount of money. We disassembled the solar panel light as it was in a cheap plastic container. Were then removed the circuit and all components from the cheap plastic container. We did this so we could modify the circuit and add brighter LED’s.

After we disassembled the circuit we put all the pieces into a bag. We then began to make the aluminium box. Terry had all the templates of the box already cut to save time. The aluminium template was cut in the cam machine because it is a lot faster than manually cutting it.

We first marked lines on the aluminium template that showed were the bending points were. We then folded the sides that stuck out of the aluminium template at 90 degree angles. After all 4 sides were bent the aluminium template formed a box shape.

Then after the box was folded we made brackets for it. These were made by cutting out bits out of the scrap aluminium with the guillotine .We marked the bending points in the bits of scrap aluminium then bent them into shape – Bending bit of scrap aluminium at a 90 degree angle so they were ‘L’ shaped. We then marked out the points were the rivets could go through we drilled them out using a 2.5 drill bit. We had to put the holes in specific places to prevent the rivets from hitting each other when inserted in the box. Then we attached the brackets onto the box. The bottom of the box was now completed.

The next step was to create the top plate of the box this again was cut out with the cam machine to save time. We marked out the folding points then bent the edges at a 90 degree angle. Then drilled holes and attached it to the bottom of the box using screws. Modifying The Circuit The circuit had to be modified. We modified it by Adding two stronger and brighter LED’s (there used to be one weak LED before undergoing modification) We also changed the circuit from series to parallel. In the process of changing the circuit from series to parallel I had a problem. The problem was that the circuit didn’t work. I did a complete analysis of the circuit and to my dismay I discovered that my wire connection to the circuit board had broken so I had to re-solder the joint. This corrected the functionality of my circuit We also added a new battery connector. Once my circuit was working I attached it into my Aluminium box. Then I discovered another problem. The wire connection was touching the aluminium box and causing the circuit to short circuit. So I took out the circuit of the box and disconnected the wire connection and placed heat shrinkable tube and made sure all other connections had heat shrinked tube on them to prevent short circuiting. This solved my problem.

I then attached the solar panel to the circuit. I made the LED’s stick out of the box and the stayed there with hot glue. The solar panel was stuck onto the box with silicon. The light now works as it should.

This process was completed within the given time frame

Chirag =)

Tuesday, July 1, 2008

Week 9 Term 2

last friday i finished my circuit.allthough i had 1 problem - my circuit was not working in the aluminium box.I found out that i had forgotten to put a rubber tube thing on a connection of wires so i disconnected that connection of wires and put the rubber tube thing on then heat shrinked it.the circuit now works in the box.i then attached the solar panel to the box with silicon.yesterday i worked on solid works and uploaded images of my rendered solid works image .today im doing an engineering drawing of my design

Monday, June 30, 2008

week 5 term 2

On tuesda i uploaded my breif that i wrote in term 1 onto my blog this is an assential part of my project.today im doing reflections and my calender on friday i was working on my box i got alot done

Tuesday, June 24, 2008

week 8 term 2 08

This week i have mainly been doing solid works.my whole light is complete on solid works i added images of each part of my light (the base, top part, dimmer knob, and the solar panel ) and the fully assembled light.i had a bit of trouble creating the dimmer knob on solid works i couldnt make the shape but then jono helped create it

Monday, June 23, 2008

Tuesday, June 17, 2008

Week 7 term2 08

On Tuesday I put some more pictures of my modified circuit in progress.I also have used solid works to make a 3D vesion of my light so far i have made a base and the light part i have assembled the 2 parts together.today i will be making the solar panel and the dimmer nob

Monday, June 16, 2008

Subscribe to:

Posts (Atom)